A fork lift free future!

FlexQube, the number one supplier of flexible carts to tugger trains!

UPDATE: FlexQube will be exhbiting at LogiMAT 2018 in Stuttgart. Our CTO Per Augustsson, will also be speaking about the future of material handling. If you are looking into a forklift free future, feel free to reach out to your local sales manager at sales@flexqube.com

CTO reflections from LogiMAT 2014, Stuttgart

The trend at LogiMat 2014 was very clear. The future of material handling is fork lift free. And finally it seems that also the major fork lift manufacturers have realized this. Both Jungheinrich and Linde Material Handling released their new tugger train solutions at the trade show. STILL, the most established supplier of tugger trains, demonstrated updated versions of their popular E-frame. The range of simple and pure mechanical tugger train solution sare also increasing a lot!

Tugger train is one of the most efficient ways of replacing the fork lift. This means transporting carts, loaded with material, in a train where each cart can be removed from the train independent of each other. This is possible thanks to the “mother/daughter” principle that most suppliers use.

When customers invest in a tugger train solution they invest in a system. A system that will be used for many years ahead in their plants. They are investing in a complete package that includes both the tugger trains, but just as important, the carts to transport! For one single tugger train a customer might need to invest in hundreds of carts. In most cases the investment in carts exceeds the tugger train cost. So what will this mean? In order to get the best possible return of investment for the carts, the customer must be able to change their carts over time to adapt to new needs and trends. That is for sure. Looking at the history, things will change. And it will change faster and more frequent.

Finally, the most interesting conclusion from LogiMat 2014. Not one single tugger train supplier offers flexible carts. Welded and inflexible carts are the only alternative. In one way that is logical. Development and sales of world class carts requires completely different knowledge and skills than selling tugger trains and fork lifts.

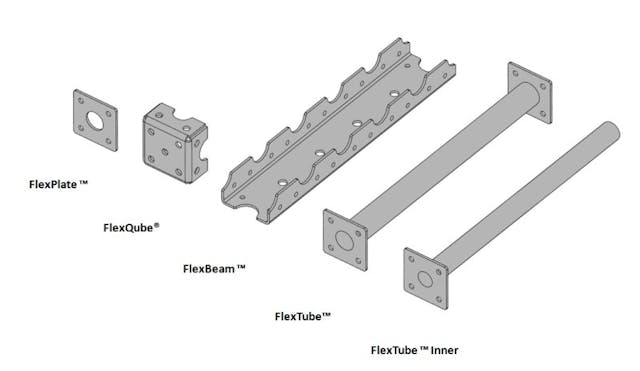

This knowledge is exactly what FlexQube offers, and we are constantly developing our knowledge in the area of flexible carts to tugger trains.

FlexQube will be the number one global supplier of carts to tugger trains! Our aim is to offer flexible base carts (platforms) to all brands and variants of tugger trains. And we will have the most innovative tools to help customers find the best cart solution connected to their need and choice of tugger train.

If you are looking for a heavy duty and flexible solution for your material handling needs or at looking towards a forklift free future please reach out to sales@flexqube.com and we will come back to you as soon as we can!

FlexQube’s top 5 industrial push carts.

Find all of our best selling flat deck tugger carts here.

Find all of our best selling shelf carts here.

/Qube it!™